LEED Building Boom - Great Opportunity for Washout Service Providers

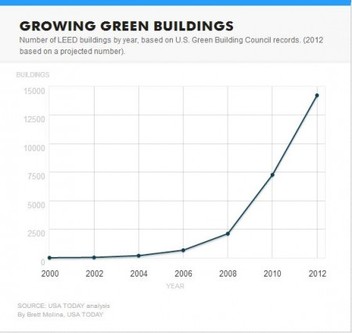

Looking at LEED certified building growth alone you might well be surprised that the construction industry has yet to emerge from a historic slowdown. Interest in environmentally sensitive building and energy savings, along with government tax incentives, have helped fuel a five-fold increase in the number of LEED certified buildings in just the past four years. Under LEED, builders get credit for recycling building materials and reducing waste - CWS licensed washout providers deliver both to LEED builders. Since credits are given on the basis of the weight of residual concrete and the water that CWS providers recycle and treat, washout providers can offer credits relatively inexpensively. Research conducted by CWS indicates that approximately 300 million gallons of corrosive concrete washout liquid waste is produced each year, an amount equal to 27 Exxon Valdezs a year.

What is more, since almost every new LEED construction project uses concrete extensively, CWS service providers have a prospective customer in every LEED builder. If this growth continues, along with a resurgence in building in general, it's conceivable that CWS providers may easily see a five to ten-fold increase in LEED customers over the coming four years. Each provider should make sure they are well known to area architects and specialists in green building (the USGBC is a very good resource) and should tailor promotional materials to showcase the valuable LEED credits builders will receive by using a CWS provider.

Links of interest: USGBC (United States Green Building Counsel); Upcoming USGBC Greenbuild Conference in San Franicsco, Nov 12-16.

Important Revision of LEED v4 Available for Draft Comments

With LEED presenting a significant driver for your future growth, you'll want to make sure your voice is heard and concrete washout waste is properly accounted for within the new LEED standards. It's easy to submit your comments online, although you should allow a little time to find the appropriate section and to fine-tune your comments, since they cannot be revised once they are submitted. While you don't have to be a USGBC member to comment, you'll need to register. These revisions, much like your state or local regulations, are only infrequently revised, which means your attention is urgently needed.

Please help grow your business by getting involved! Click here to go to the LEED v4 draft page.

CWS Locator - Don’t Lose Your Listing!

Renew your CWS Locator subscription now before the price increases. You don't want to lose your company’s listing on the CWS Locator which resides conveniently on the the number one website in our industry: www.concretewashout.com. Each county listing is only $299 per county per year, which can be reduced with the following discount.

One of the best training resources is available to our customers for FREE. You may have seen the CWS Welcome Video (it was originally produced as a DVD). The video is approximately 40 minutes long and consists of an interview with CWS founder, Mark Jenkins along with visual footage of a thriving CWS operation. The purpose of the video is to give owners and employees answers to the most frequently asked questions as well and provide a basic understanding of a typical CWS operator's facility. Every employee should view this video. The video is now available online to CWS customers. Please contact us for the links to this must-see video. The Case for Concrete Washout Control

Despite the fact that CWS customers have played a leading role in containing a harmful environmental pollutant and reducing builder liability for years, in some areas regulators remain unaware of the concrete washout problem, which can leave you with responsibility of helping them get up to speed. Toward this end, we offer a letter submitted to the California State Water Resources Control Board. We hope that you find some of the ideas useful in promoting the EPA's BMPs (Best Management Practices):

Dear Ms. Townsend,

In reference to the Public Comments for the Construction General Permit, I hereby submit this comment letter to the California State Water Resources Control Board.

My name is Mark Jenkins. I am the President of Concrete Washout Systems, Inc., a Sacramento-based company that develops cost-effective technologies to prevent environmental pollution, to enable best management practices (BMPs) in the construction industry, and to encourage sustainable development. I am also president of Jenkins Concrete, and have been a concrete contractor for over thirty years. I have done virtually every job on a construction site, so I understand the challenges facing the construction industry. I have also seen first-hand the impact our industry has had on our environment, and have dedicated myself to reducing our environmental impact.

The Concrete Washout Wastewater Problem

I would like to address the important issue of the secure containment and safe disposal of concrete washout wastewater — one of the most harmful and widespread pollutants created by the construction industry. Concrete washout wastewater results from washing down equipment such as concrete trucks, pumps, mixers, chutes, tools, and wheelbarrows. It is the most common discharge from concrete construction, and it is caustic and corrosive, with a pH of 12 or higher (essentially the same as Liquid Drano). It carries concrete particulate residue in suspension, and contains contaminants including aluminum, barium, chromium, hexavalent chromium (chromium 6), copper, iron, magnesium, manganese, nickel, potassium, selenium, sodium, vanadium, and zinc. The washout wastewater can also contain trace elements of petroleum products, admixtures, and other materials from processing or treating the material. In our research we have found that over 300 million gallons of washout wastewater are emitted by construction activities annually — one gallon for every man, woman and child in the US, or the volume equivalent of 27 Exxon Valdez tanker spillsper year.

Environmental Risks

Concrete washout wastewater poses potential risks to plant life; fish and other wildlife; and to human health. Direct contact with the high-pH washout water can cause skin irritation, severe chemical burns, or serious eye damage. Contaminants and heavy metals in the water such as chromium, selenium, vanadium, and other heavy metals are understood to pose health hazards to humans. When washed into the storm drain, washout wastewater can harm aquatic life. The effects of high pH on fish can include death; damage to outer surfaces like gills, eyes, and skin; and an inability to dispose of metabolic wastes. High pH may also increase the toxicity of other substances found in the water. For example, the toxicity of ammonia is ten times more severe at a pH of 8 than it is at pH 7. The safe range for aquatic life is between 6.5 – 9.0 pH units, significantly below the pH of 12 of concrete washout water. In addition, concrete solids in suspension can increase turbidity, reducing the ability of fish to function normally in their habitat.

If caustic washout liquid is allowed to spill onto the ground it can harm plant life and soil quality. The effects of high pH on vegetation may include inhibited growth, damage to soil and plants, and substantial alteration of the soil and plant chemical composition, even after the pollution source is gone. High pH may also increase the toxicity of other substances causing further problems. The safe range for plant life is between 6.5 – 7.0 pH units. Once in the soil, contaminants can remain there indefinitely, potentially creating “brown field” problems requiring remediation. This can create second-order environmental problems, as healthy vegetation is the best way to prevent soil erosion, which is another major source of runoff pollution. Equally as significant, wastewater leaching into the soil can find its way into the water table, affecting the quality of drinking water and the ecosystem.

It is for these reasons that the US EPA stipulates that concrete wash water “…should not be discharged to any surface water, storm sewer system, or allowed to infiltrate into the ground.” (US EPA: Developing your Stormwater Pollution Prevention Plan: A Guide for Construction Sites, May 2007.)

Many of Our Current Practices Are Insufficient

The most frequently used means to contain concrete washout at the construction site is the washout pit. These pits are generally dug into the ground, lined with a thin plastic sheet, and surrounded by hay bales. Even though they are at present considered to be an acceptable management practice, the pits are a very unreliable containment method. Over time, the plastic liner and hay bales wear and break down; and, usually, the liner is breached by normal construction activity at the work site. Oftentimes the liner is purposefully torn by jobsite personnel to allow the wastewater to run off so more trucks can wash out in the pit. Once breached, the corrosive wastewater easily escapes into the ground or to the stormwater system. Moreover, most jobsites require the use of large concrete pump trucks. Concrete pump trucks have a very low hanging hopper in the back of the truck that prevents use of a bale-lined pit for washing out. Consequently, pumpers generally wash out directly on the ground whereby wastewater either leaches into the soil, or flows onto pavement and into a storm drain.

When a contractor removes a pit, the solid concrete waste is broken up, excavated, and sent to landfill—not recycled. (since plastic liner is bound up in the concrete solids, concrete recycling plants will not accept an otherwise 100% recyclable resource). The corrosive wastewater, however, is left behind in the soil, along with all its contaminants. Other methods frequently encountered, such as dumpsters lined with thin plastic sheeting, plastic garbage cans, etc., have similar problems: the washout wastewater leaks from the smallest breach, and pump trucks are generally unable to wash out in them.

Recommendation

Concrete washout wastewater should be securely contained at construction sites until it can be removed without spillage, and the water should be safely treated by a facility suitable for this purpose. In order to encourage this practice, I would ask the Water Resources Control Board to consider requiring a secure, self-contained, and watertight container designated for concrete washout at all construction sites.

If I may also suggest, as a best management practice, that concrete washout wastewater be tracked from origin to ultimate safe disposition, through the use of manifests and weight tickets — as is already the case for motor oil and similar discharges. This practice would ensure the complete removal and safe disposal of this pollutant. We need to be confident that untreated concrete wastewater does not enter the environment at any point in the process.

Cost-Effective Solutions Already Available

The industry has developed and successfully implemented BMPs that are more reliable, economical, and environmentally sustainable than plastic-lined pits. Additionally, many of these solutions are 100% recyclable. My company, Concrete Washout Systems, is one of several providers of portable self-contained units that can securely contain concrete washout water and solids at the construction site; reliably remove pollutants from the site; safely treat the wastewater; and fully recycle the concrete solids—which are commonly re-used for roadbed and other construction uses. We consider this a “win-win” solution, since the concrete solids are recycled, thus enabling large volumes of unnecessary landfill waste to be diverted. At the same time, the polluting wastewater is contained and treated. Our solution is already in use in over a dozen states in the US and in Canada, and has been incorporated by major stakeholders in the construction industry, including commercial homebuilders, municipalities, contractors, SWPPP and consulting engineers, concrete pump truck operators and manufacturers, environmental regulators, and many others. I believe that we are only one of many providers that can offer a commercially viable solution to address this significant environmental challenge, that is also 100% recyclable, and reduces the impact on our limited landfill space.

Conclusion

I hope the Water Resources Control Board will require that a self-contained, portable, and watertight container be designated on every concrete construction site for concrete washout — along with reliable and verifiable processes to ensure the secure containment, controlled removal, and safe disposal of concrete washout wastewater. We are encouraged that CalTrans has already taken a strong leadership role in this regard, specifying this type of BMP for concrete washout as a requirement for its most recent construction projects. I also hope that the state of California continues to lead the country in environmental stewardship, and in this regard, I suggest that the Board also recommend the full recycling of concrete solids, a renewable resource and a significant opportunity for landfill diversion. Thank you for your consideration.

Sincerely yours,

Mark Jenkins, President

Quotes:

"Procrastination is opportunity's assassin." -Victor Kiam

Looking at LEED certified building growth alone you might well be surprised that the construction industry has yet to emerge from a historic slowdown. Interest in environmentally sensitive building and energy savings, along with government tax incentives, have helped fuel a five-fold increase in the number of LEED certified buildings in just the past four years. Under LEED, builders get credit for recycling building materials and reducing waste - CWS licensed washout providers deliver both to LEED builders. Since credits are given on the basis of the weight of residual concrete and the water that CWS providers recycle and treat, washout providers can offer credits relatively inexpensively. Research conducted by CWS indicates that approximately 300 million gallons of corrosive concrete washout liquid waste is produced each year, an amount equal to 27 Exxon Valdezs a year.

What is more, since almost every new LEED construction project uses concrete extensively, CWS service providers have a prospective customer in every LEED builder. If this growth continues, along with a resurgence in building in general, it's conceivable that CWS providers may easily see a five to ten-fold increase in LEED customers over the coming four years. Each provider should make sure they are well known to area architects and specialists in green building (the USGBC is a very good resource) and should tailor promotional materials to showcase the valuable LEED credits builders will receive by using a CWS provider.

Links of interest: USGBC (United States Green Building Counsel); Upcoming USGBC Greenbuild Conference in San Franicsco, Nov 12-16.

Important Revision of LEED v4 Available for Draft Comments

With LEED presenting a significant driver for your future growth, you'll want to make sure your voice is heard and concrete washout waste is properly accounted for within the new LEED standards. It's easy to submit your comments online, although you should allow a little time to find the appropriate section and to fine-tune your comments, since they cannot be revised once they are submitted. While you don't have to be a USGBC member to comment, you'll need to register. These revisions, much like your state or local regulations, are only infrequently revised, which means your attention is urgently needed.

Please help grow your business by getting involved! Click here to go to the LEED v4 draft page.

CWS Locator - Don’t Lose Your Listing!

Renew your CWS Locator subscription now before the price increases. You don't want to lose your company’s listing on the CWS Locator which resides conveniently on the the number one website in our industry: www.concretewashout.com. Each county listing is only $299 per county per year, which can be reduced with the following discount.

- Save $50 per year when you pay for two years (only $498 per county for 26 months when you pay by October 31)

- It’s the easiest way for LEED builders that love CWS to find you for their local jobs

- Is the fastest way for any builder to locate your business

- Has the power to increase your company’s search engine optimization when you add a link to your listing

One of the best training resources is available to our customers for FREE. You may have seen the CWS Welcome Video (it was originally produced as a DVD). The video is approximately 40 minutes long and consists of an interview with CWS founder, Mark Jenkins along with visual footage of a thriving CWS operation. The purpose of the video is to give owners and employees answers to the most frequently asked questions as well and provide a basic understanding of a typical CWS operator's facility. Every employee should view this video. The video is now available online to CWS customers. Please contact us for the links to this must-see video. The Case for Concrete Washout Control

Despite the fact that CWS customers have played a leading role in containing a harmful environmental pollutant and reducing builder liability for years, in some areas regulators remain unaware of the concrete washout problem, which can leave you with responsibility of helping them get up to speed. Toward this end, we offer a letter submitted to the California State Water Resources Control Board. We hope that you find some of the ideas useful in promoting the EPA's BMPs (Best Management Practices):

Dear Ms. Townsend,

In reference to the Public Comments for the Construction General Permit, I hereby submit this comment letter to the California State Water Resources Control Board.

My name is Mark Jenkins. I am the President of Concrete Washout Systems, Inc., a Sacramento-based company that develops cost-effective technologies to prevent environmental pollution, to enable best management practices (BMPs) in the construction industry, and to encourage sustainable development. I am also president of Jenkins Concrete, and have been a concrete contractor for over thirty years. I have done virtually every job on a construction site, so I understand the challenges facing the construction industry. I have also seen first-hand the impact our industry has had on our environment, and have dedicated myself to reducing our environmental impact.

The Concrete Washout Wastewater Problem

I would like to address the important issue of the secure containment and safe disposal of concrete washout wastewater — one of the most harmful and widespread pollutants created by the construction industry. Concrete washout wastewater results from washing down equipment such as concrete trucks, pumps, mixers, chutes, tools, and wheelbarrows. It is the most common discharge from concrete construction, and it is caustic and corrosive, with a pH of 12 or higher (essentially the same as Liquid Drano). It carries concrete particulate residue in suspension, and contains contaminants including aluminum, barium, chromium, hexavalent chromium (chromium 6), copper, iron, magnesium, manganese, nickel, potassium, selenium, sodium, vanadium, and zinc. The washout wastewater can also contain trace elements of petroleum products, admixtures, and other materials from processing or treating the material. In our research we have found that over 300 million gallons of washout wastewater are emitted by construction activities annually — one gallon for every man, woman and child in the US, or the volume equivalent of 27 Exxon Valdez tanker spillsper year.

Environmental Risks

Concrete washout wastewater poses potential risks to plant life; fish and other wildlife; and to human health. Direct contact with the high-pH washout water can cause skin irritation, severe chemical burns, or serious eye damage. Contaminants and heavy metals in the water such as chromium, selenium, vanadium, and other heavy metals are understood to pose health hazards to humans. When washed into the storm drain, washout wastewater can harm aquatic life. The effects of high pH on fish can include death; damage to outer surfaces like gills, eyes, and skin; and an inability to dispose of metabolic wastes. High pH may also increase the toxicity of other substances found in the water. For example, the toxicity of ammonia is ten times more severe at a pH of 8 than it is at pH 7. The safe range for aquatic life is between 6.5 – 9.0 pH units, significantly below the pH of 12 of concrete washout water. In addition, concrete solids in suspension can increase turbidity, reducing the ability of fish to function normally in their habitat.

If caustic washout liquid is allowed to spill onto the ground it can harm plant life and soil quality. The effects of high pH on vegetation may include inhibited growth, damage to soil and plants, and substantial alteration of the soil and plant chemical composition, even after the pollution source is gone. High pH may also increase the toxicity of other substances causing further problems. The safe range for plant life is between 6.5 – 7.0 pH units. Once in the soil, contaminants can remain there indefinitely, potentially creating “brown field” problems requiring remediation. This can create second-order environmental problems, as healthy vegetation is the best way to prevent soil erosion, which is another major source of runoff pollution. Equally as significant, wastewater leaching into the soil can find its way into the water table, affecting the quality of drinking water and the ecosystem.

It is for these reasons that the US EPA stipulates that concrete wash water “…should not be discharged to any surface water, storm sewer system, or allowed to infiltrate into the ground.” (US EPA: Developing your Stormwater Pollution Prevention Plan: A Guide for Construction Sites, May 2007.)

Many of Our Current Practices Are Insufficient

The most frequently used means to contain concrete washout at the construction site is the washout pit. These pits are generally dug into the ground, lined with a thin plastic sheet, and surrounded by hay bales. Even though they are at present considered to be an acceptable management practice, the pits are a very unreliable containment method. Over time, the plastic liner and hay bales wear and break down; and, usually, the liner is breached by normal construction activity at the work site. Oftentimes the liner is purposefully torn by jobsite personnel to allow the wastewater to run off so more trucks can wash out in the pit. Once breached, the corrosive wastewater easily escapes into the ground or to the stormwater system. Moreover, most jobsites require the use of large concrete pump trucks. Concrete pump trucks have a very low hanging hopper in the back of the truck that prevents use of a bale-lined pit for washing out. Consequently, pumpers generally wash out directly on the ground whereby wastewater either leaches into the soil, or flows onto pavement and into a storm drain.

When a contractor removes a pit, the solid concrete waste is broken up, excavated, and sent to landfill—not recycled. (since plastic liner is bound up in the concrete solids, concrete recycling plants will not accept an otherwise 100% recyclable resource). The corrosive wastewater, however, is left behind in the soil, along with all its contaminants. Other methods frequently encountered, such as dumpsters lined with thin plastic sheeting, plastic garbage cans, etc., have similar problems: the washout wastewater leaks from the smallest breach, and pump trucks are generally unable to wash out in them.

Recommendation

Concrete washout wastewater should be securely contained at construction sites until it can be removed without spillage, and the water should be safely treated by a facility suitable for this purpose. In order to encourage this practice, I would ask the Water Resources Control Board to consider requiring a secure, self-contained, and watertight container designated for concrete washout at all construction sites.

If I may also suggest, as a best management practice, that concrete washout wastewater be tracked from origin to ultimate safe disposition, through the use of manifests and weight tickets — as is already the case for motor oil and similar discharges. This practice would ensure the complete removal and safe disposal of this pollutant. We need to be confident that untreated concrete wastewater does not enter the environment at any point in the process.

Cost-Effective Solutions Already Available

The industry has developed and successfully implemented BMPs that are more reliable, economical, and environmentally sustainable than plastic-lined pits. Additionally, many of these solutions are 100% recyclable. My company, Concrete Washout Systems, is one of several providers of portable self-contained units that can securely contain concrete washout water and solids at the construction site; reliably remove pollutants from the site; safely treat the wastewater; and fully recycle the concrete solids—which are commonly re-used for roadbed and other construction uses. We consider this a “win-win” solution, since the concrete solids are recycled, thus enabling large volumes of unnecessary landfill waste to be diverted. At the same time, the polluting wastewater is contained and treated. Our solution is already in use in over a dozen states in the US and in Canada, and has been incorporated by major stakeholders in the construction industry, including commercial homebuilders, municipalities, contractors, SWPPP and consulting engineers, concrete pump truck operators and manufacturers, environmental regulators, and many others. I believe that we are only one of many providers that can offer a commercially viable solution to address this significant environmental challenge, that is also 100% recyclable, and reduces the impact on our limited landfill space.

Conclusion

I hope the Water Resources Control Board will require that a self-contained, portable, and watertight container be designated on every concrete construction site for concrete washout — along with reliable and verifiable processes to ensure the secure containment, controlled removal, and safe disposal of concrete washout wastewater. We are encouraged that CalTrans has already taken a strong leadership role in this regard, specifying this type of BMP for concrete washout as a requirement for its most recent construction projects. I also hope that the state of California continues to lead the country in environmental stewardship, and in this regard, I suggest that the Board also recommend the full recycling of concrete solids, a renewable resource and a significant opportunity for landfill diversion. Thank you for your consideration.

Sincerely yours,

Mark Jenkins, President

Quotes:

"Procrastination is opportunity's assassin." -Victor Kiam

RSS Feed

RSS Feed